Directional Woven Fibers

Woven Fabric materials are used in the wet-wrapping process.

- Materials can be E-glass, S-glass, carbon fiber, woven or stitched together to form strong fabric.

- For oilfield applications, we use directional fiber that is 50/50 or 90/10 and 3-D weave.

- Weight ranges from 1 oz./yard to 600 oz./yard depending on the needs.

Common weave patterns used in oil and gas applications

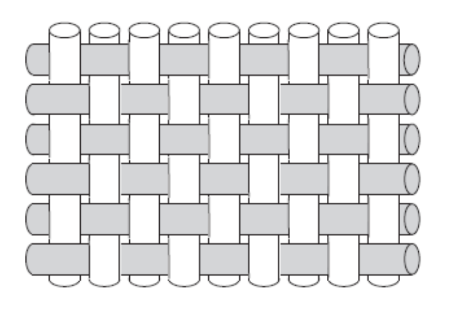

Plain Weave

- Fiber is interlaced in an alternating pattern

- Has good fabric stability

- Most common fabric used in electronics and coating industries

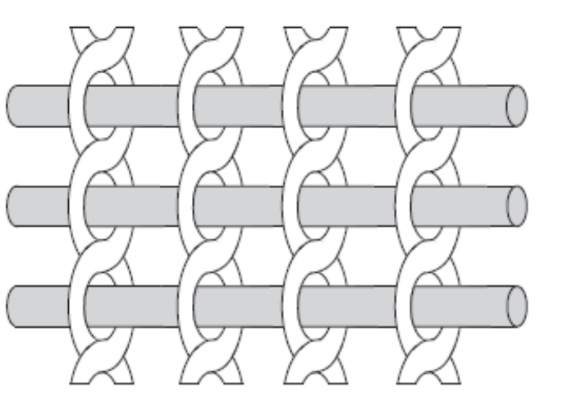

Leno

- Used where relatively low aerial weights but specific thickness needs to be the same

- This fabric is commonly seen in EIFS applications and to set bond line thicknesses for adhesives

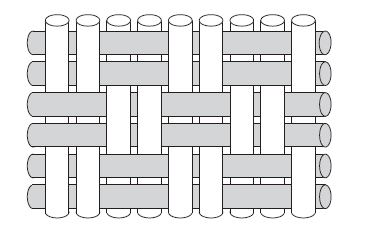

Basket Weave

- Similar to plain weave except that two or more fibers are alternately interlaced over and under one another

- More pliable, flatter and stronger than plain weave, just not as stable

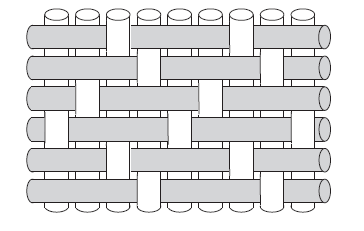

4H Satin

- Relies on three by one interlacing pattern

- The fiber floats over three warp fibers and under one

- Better at conforming to curved surfaces plus more pliable than plain weave

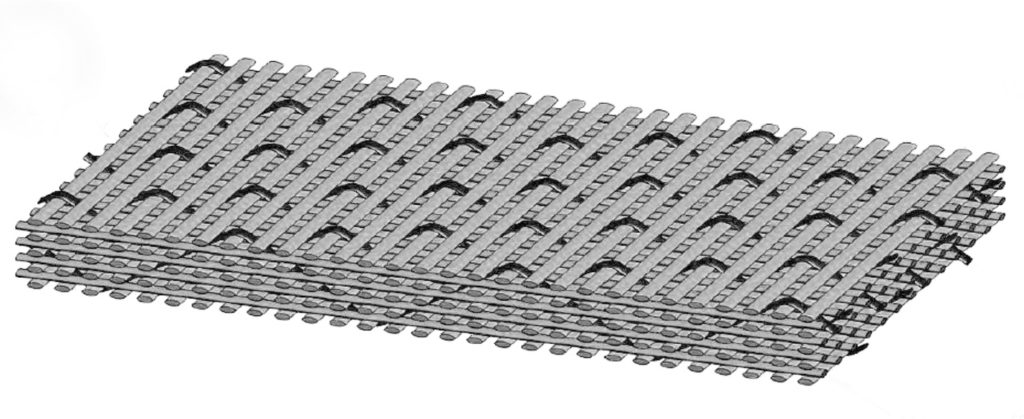

3D Woven Fabric

- 3D woven fabric is 3-Dimension fabric

- Fiberglass makes up the 3D woven fabric that adds strength, which is similar to steel, but is not high in weight

- Compared to a 2D fabric it has limited delamination due to the 3D weave

- The 3D woven fabric has a shorter process time