Quality Team Ensures Strength Requirements and Performance Needs

Proven Leader in Composites

Industry-leading techniques and tools ensure your products are inspected and meet your demanding specifications and requirements. Through a culture of teamwork, quality control is integrated in all aspects of our company, using accountability, communication, and innovative quality systems and resources.

Industry-leading techniques and tools ensure your products are inspected and meet your demanding specifications and requirements. Through a culture of teamwork, quality control is integrated in all aspects of our company, using accountability, communication, and innovative quality systems and resources.

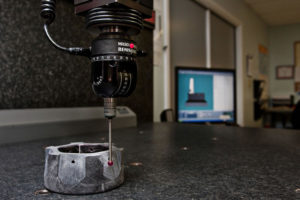

Our Quality Control department uses industry-leading techniques and tools to inspect products per customer requirements.

- Quality assurance plan

- Quality engineers

- Industry-leading inspection tools

- Documented inspection test plans and procedures

- Technically proficient inspectors

- Adapted quality requirements per customer specifications