Composite Manufacturing

Manufacturing on the cutting edge.

Composite manufacturing is the core of GP&C’s legacy and our continued innovation. Our engineers optimize fiber placement, resin systems, and curing processes to produce lightweight, high-strength components that meet demanding performance specifications. The result is custom solutions that are both advanced and cost-effective.

From prototype to production, our processes are tailored to meet precise specifications, ensuring consistency, reliability and Precision in Every Fiber at every stage.

Manufacturing Processes

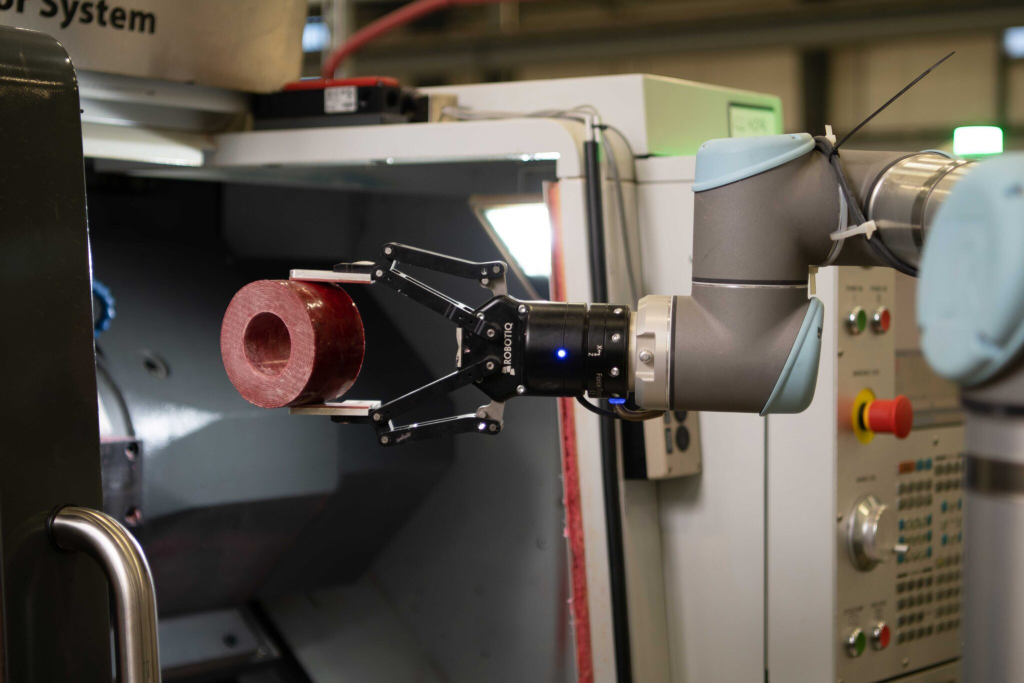

Filament Winding

A computer-controlled, multi-axis process that winds continuous fibers under precise tension and angle around a mandrel. Our engineers define fiber orientation to meet specific mechanical requirements, producing consistent, high-performance composite structures with optimal strength and material efficiency.

Additive Manufacturing

Our 3D composite manufacturing utilizes fiber-reinforced polymer materials to produce small-to-medium-sized components with exceptional strength-to-weight ratios and high-temperature performance. By combining additive manufacturing precision with advanced composite materials, we create parts that maintain structural integrity under demanding mechanical and thermal conditions.

Wet Wrapping

A manual process in which fiberglass reinforcement is hand-applied around a mandrel while resin is impregnated into the fibers. Though labor-intensive, wet wrapping is ideal for thicker cross-sections or components with lower mechanical loads, offering flexibility and control in small-volume production.

Compression Molding

Compression molding involves placing a pre-measured elastomer or thermoset composite charge into a heated mold cavity and applying pressure for a defined time and temperature cycle. This process is ideal for layered or multi-material components, delivering precise dimensional control and uniform properties.

Injection Molding

Injection molding supports high-volume production through rapid, repeatable cycles. A predetermined quantity of elastomer is heated to optimal viscosity and injected into the mold cavity, where it cures under controlled temperature and pressure to produce consistent, dimensionally stable parts.

Transfer Molding

In transfer molding, a pre-measured elastomer charge is placed in a transfer pot and forced by a piston through a sprue system into the mold cavity. Controlled temperature and cure time ensure complete filling of detailed features and encapsulation of inserts or complex geometries.

Vacuum Assisted Resin Transfer Molding (VARTM)

In this closed-mold process, dry fiberglass reinforcement is vacuum-sealed to remove moisture and air before resin is introduced under pressure. The result is a high fiber-to-resin ratio and void-free structure — ideal for parts requiring superior mechanical strength and dimensional precision.

Resin Transfer Molding (RTM)

In this closed-mold process, a dry fiber preform is placed into a rigid mold and injected with thermoset resin under controlled pressure. The resin fully wets the fibers and cures inside the mold, producing a strong, dimensionally accurate composite part with consistent quality.

Pre-Preg Layup

Pre-impregnated fiber materials are hand-laid in precision molds according to defined ply orientations, then vacuum-bagged and cured under heat and pressure. This method delivers tight dimensional control and exceptional performance for complex geometries and low-volume applications.