Advanced Bonding & Assembly

Providing integrity under pressure.

We design and manufacture components and assemblies to meet precise mechanical, thermal, and environmental specifications, uniting composite, elastomeric, and metallic structures into cohesive systems that deliver maximum strength and durability to deliver unmatched performance. Fully qualified assemblies are supplied production-ready, minimizing integration challenges.

Leveraging decades of experience, we select the most effective joining solution — structural adhesives, co-molding or mechanical fastening — then each bond or joint is engineered for long-term integrity under mechanical, thermal, and environmental stress and finally, validated through in-house testing.

Capabilities include:

Adhesive & Co-Molding

We can perform structural bonding and co-mold composites and metals with elastomers and some adhesive.

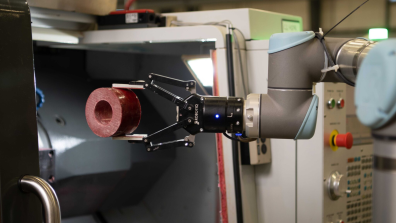

Mechanical Fastening

We offer precision-engineered joint design through optimized selection of fastener type, material and placement depth to achieve reliable load transfer and long-term structural performance.

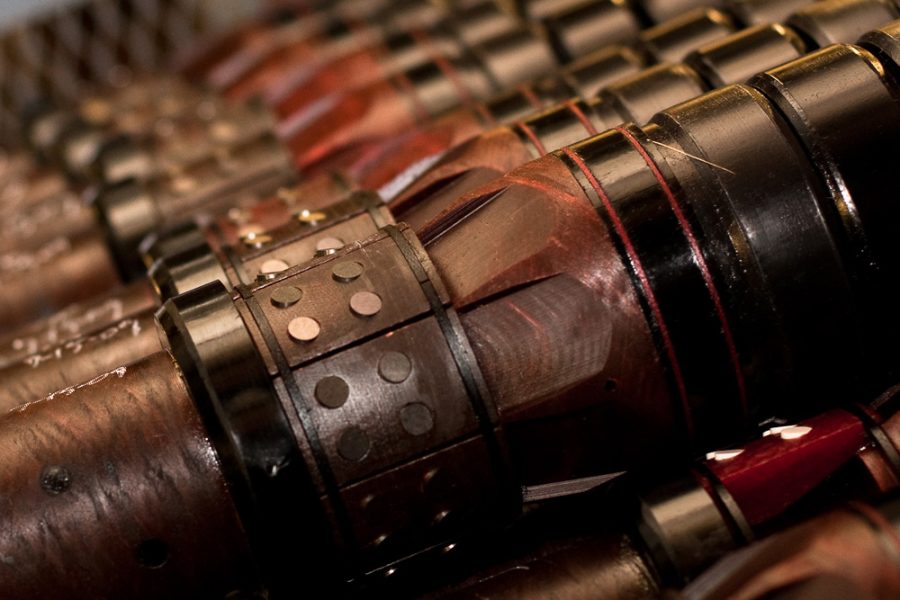

Complex Wire Grooves and Threads

GP&C engineers and machines proprietary composite threads and precision wire grooves that enable electrical functionality within structural components.

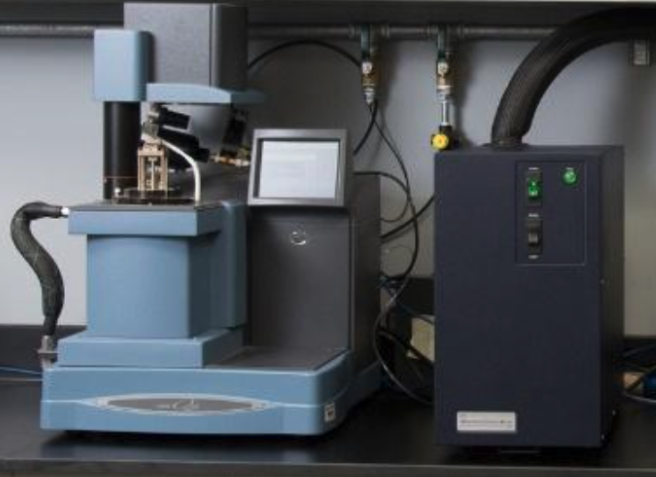

Testing & Validation

GP&C’s in-house lab is equipped for advanced material and performance testing, including dynamic mechanical analysis (DMA) and differential scanning (DSC) to determine Tg and verify cure profiles and more. Our engineers work directly with customers to define and execute qualification test plans for both materials and assemblies.