Material Science

Material science is central to GP&C’s promise of Precision in Every Fiber.

We blend advanced woven materials, individual rovings, and engineered resin systems to create predictable, high-performance composite structures. Guided by continuous improvement, we actively pursue emerging fibers, resins, and processing technologies to elevate strength, reduce weight, and deliver industry-leading performance in every part we produce.

Our Material Science Expertise

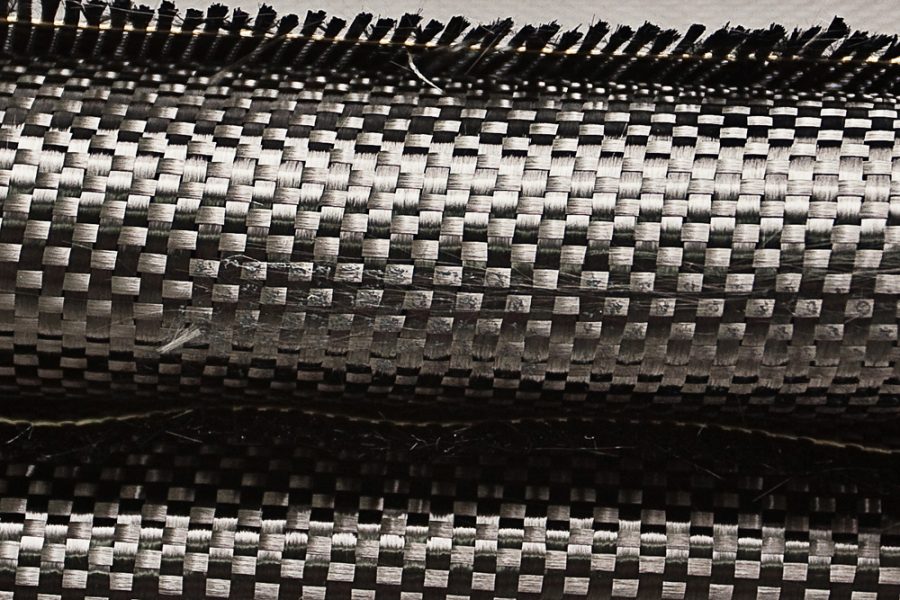

- Engineered Fiber Architectures: Use of woven fabrics, unidirectional rovings, and hybrid reinforcements tailored to specific mechanical and environmental requirements.

- Advanced Resin Systems: Selection and formulation of epoxy, phenolic, and specialty resins to deliver optimal strength, temperature resistance, and durability.

- Fiber–Matrix Optimization: Deep understanding of how fibers and resins interact to achieve predictable, repeatable performance across every part.

- Testing & Validation: Rigorous material evaluation to confirm mechanical properties, chemical compatibility, and long-term stability.

- Continuous Innovation: Ongoing sourcing, qualification, and integration of new materials and chemistries to unlock higher performance and industry-leading solutions.

Material Science Testing

Material performance begins at the molecular level. GP&C’s material science testing capabilities are designed to validate, refine, and advance composite material systems before they ever reach production. Our team applies standardized testing, thermal analysis, and process studies to understand how materials behave—during manufacturing and in service—ensuring consistency, repeatability, and performance at scale.

Through rigorous evaluation and continuous development, we optimize resin systems, fiber reinforcements, and cure profiles to meet evolving application demands while maintaining tight process control.

Material Science Testing Capabilities Include:

- ASTM material testing – Verification of material properties against industry standards

- New epoxy development – Thermal and mechanical characterization using DSC (Differential Scanning Calorimetry) and DMA (Dynamic Mechanical Analysis)

- New glass reinforcement evaluation – ASTM testing and DMA to assess performance and compatibility

- Rheology & resin behavior

- Gel time analysis

- Viscosity-temperature profiling

- Refractive index measurement of epoxy systems

- Manufacturing process studies – Evaluation of process changes to improve material control, consistency, and repeatability

- Cure kinetics analysis – Monitoring and modeling the effects of cure cycles on epoxy behavior to optimize performance and manufacturability

By combining material science with real-world manufacturing insight, GP&C delivers engineered material solutions that are proven, scalable, and tailored to each application—reinforcing our commitment to Precision in Every Fiber.

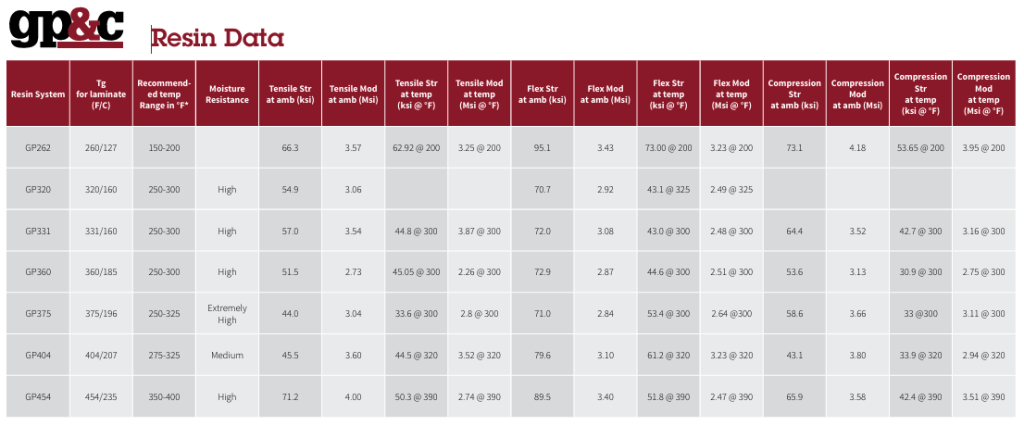

Resins Reinforce Materials

Resins are a catalyzed epoxy polymer used to impregnate the reinforcement to make a stronger and lighter material. General Plastics & Composites utilizes many different resin systems and cloth/roving combinations to meet each part or assembly’s mechanical loading and environmental requirements. Material strength depends on manufacturing method, and reinforcement cloth weave / roving size and orientation. Our Materials Science department develops custom resin systems utilized with proprietary materials. Our engineers and technicians will work jointly with you to choose the best composite materials and manufacturing methods for construction.