Prototyping with Purpose: De-Risking Composite Design

In composite manufacturing, prototyping isn’t just a checkpoint—it’s a safeguard. With so many variables at play—fiber type, orientation, resin chemistry, curing process—moving straight from concept to production is a gamble. Prototyping reduces that risk, turning uncertainty into confidence.

Why Prototyping Matters

Composites are inherently complex. Unlike metals, their performance depends not only on material choice but also on how they’re engineered and processed. A design that looks good on paper can fail in practice if fiber layups shift, resin flow stalls, or tolerances stack up. Prototyping allows engineers to validate each of these factors in real-world conditions.

Digital prototyping and simulation tools—such as finite element analysis (FEA), resin flow modeling, and cure kinetics models—are often used as a first step to narrow down viable designs before physical builds. Still, only representative prototypes can confirm the interaction of fiber architecture, geometry, and processing at scale.

Benefits of Purposeful Prototyping

A strong prototyping program provides:

- Validation of assumptions: Do the fibers align and cure as expected?

- Early detection of flaws: Catching voids, delamination, or resin-rich areas before they scale.

- Design optimization: Refining fiber orientation, thickness, or resin systems for peak performance.

- Cost control: Identifying manufacturability issues before committing to full tooling or production runs.

- Process validation: Verifying that lab processes translate effectively to production scale—whether autoclave, out-of-autoclave, resin transfer molding, or filament winding.

- Regulatory readiness: Generating test data needed for compliance.

- Performance in harsh environments: Testing under thermal cycling, chemical exposure, and fatigue loading for aerospace, oil & gas, and defense.

From Iteration to Innovation

Prototyping isn’t just about risk management—it’s also about innovation. Iterative builds allow engineers to experiment with novel layups, hybrid materials, or new process parameters without putting full programs at stake. Every prototype is both a test and a learning opportunity, feeding back insights that sharpen the final product.

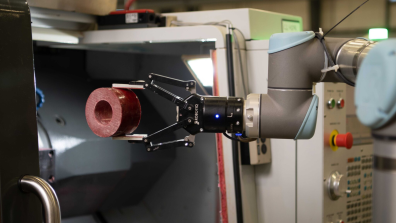

Rapid prototyping tools—such as additive manufacturing for tooling, automated fiber placement trials, and 3D-printed mandrels—accelerate iteration cycles. This allows hybrid solutions to be explored, such as metal-composite integration or thermoplastic versus thermoset evaluations.

GP&C’s Approach

At GP&C, prototyping is woven into everything we do—from aerospace to oil & gas to sporting goods. We treat prototypes as more than samples; they are engineered proofs of performance. Our cross-functional teams—design, process, quality, and testing—collaborate early to ensure every detail is addressed. Tailored test matrices link directly to customer requirements, from tensile and compressive strength to interlaminar shear, fatigue, and environmental durability.

We combine customer collaboration, tailored quality plans, and structured timelines with data-driven decision making, ensuring that prototype results refine digital models and reduce downstream certification burdens. Every prototype serves a clear purpose: to de-risk design, validate performance, and accelerate success.

At GP&C, prototyping transforms uncertainty into confidence. By combining advanced digital modeling, rigorous physical validation, and close customer collaboration, we ensure every prototype not only reduces risk but also accelerates innovation—delivering precision in every fiber.