Composite Testing Standards: What’s New and What’s Coming

In the world of composites, performance isn’t just about what a material can do—it’s about proving it. That’s where testing standards come in. From aerospace to oil & gas to sporting goods, industries rely on standardized methods to measure how composites handle stress, fatigue, temperature, and impact. These standards create a common language of reliability.

What’s New

Recent updates in composite testing have focused on consistency and data quality. New ASTM and ISO standards emphasize tighter control of variables like specimen preparation, environmental conditioning, and loading rates. This is especially important for advanced fibers and resin systems, where small variations can dramatically affect results.

Another area of progress is nondestructive evaluation (NDE). Ultrasonic, X-ray CT, shearography, and thermographic methods are being formalized to catch flaws earlier and reduce the cost of destructive testing. These tools are helping manufacturers validate parts faster while maintaining confidence in structural integrity.

Emerging standards are also addressing additive manufacturing of composites—a fast-growing area where specimen design, fiber alignment, and void content require new testing approaches.

What’s Coming

Looking forward, three major trends are shaping the next wave of standards:

1. High-Temperature and Harsh Environment Testing

With composites moving deeper into oilfield applications and higher into aerospace, expect expanded standards for performance in extreme heat, pressure, cryogenic conditions, and chemical exposure.

2. Lifecycle and Sustainability Metrics

As industries push for greener solutions, testing will evolve beyond strength and stiffness. Standards will increasingly measure recyclability, environmental degradation, microplastic release, and end-of-life performance of fiber/resin systems.

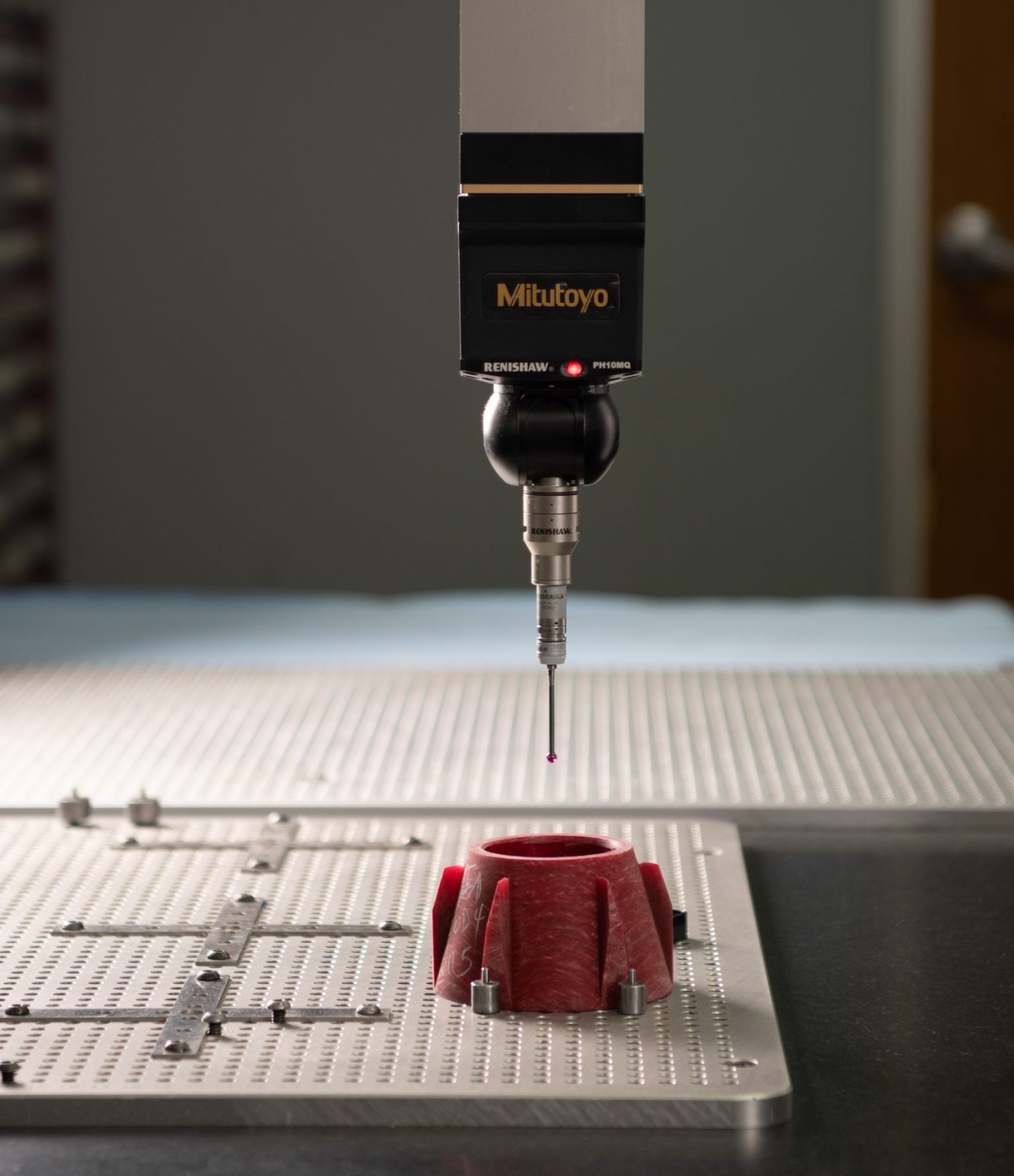

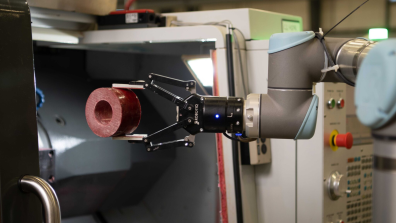

3. Digital Transformation in Testing

Automated test rigs, digital twins, and AI-driven analysis promise faster, more reliable data collection. Integration with Industry 4.0 and predictive modeling will enable virtual testing environments to complement physical standards, reducing lead times and material waste.

Additionally, organizations such as NADCAP and SAE are driving new certification requirements for aerospace, while API and ISO continue to expand oil & gas testing specifications—pushing all sectors toward harmonized global standards.

Why It Matters

For engineers, updated standards mean more accurate predictions of real-world performance. For operators and OEMs, they mean fewer failures and more confidence in mission-critical parts. And for the composites industry as a whole, they’re the key to broader adoption, certification, and innovation.

GP&C’s Edge

At GP&C, we don’t just keep pace with new testing standards—we design with them in mind. Our materials and processes are developed to meet rigorous certification requirements across industries. More importantly, we stay engaged with what’s coming next, ensuring our customers benefit from composites that aren’t just tested today, but proven for tomorrow.

That’s what we mean by precision in every fiber.