Why Precision Engineering Makes or Breaks Composite Performance

In composite manufacturing, materials like carbon fiber, glass fiber, and resins define what’s possible. But materials alone don’t guarantee performance. The real difference lies in precision engineering: the process of designing, tolerancing, and building composites with exactness from concept to production.

Why Precision Matters

Composites are anisotropic—their properties depend on fiber orientation, resin flow, curing conditions, and layup accuracy. A misplaced ply, an air pocket, or uneven cure can cause massive shifts in performance. Precision engineering ensures that design intent carries through to real-world reliability.

From Design to Reality

Every stage of engineering demands accuracy:

- Modeling: Simulations predict how fiber orientation, thickness, and resin systems interact.

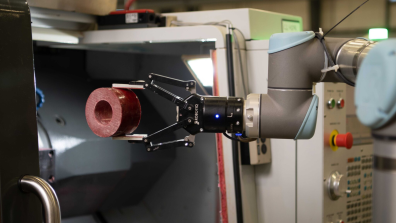

- Tooling: Precise molds ensure parts meet tight tolerances.

- Process control: Heat, pressure, and timing are engineered to lock in performance.

- Inspection: Nondestructive evaluation catches hidden errors.

- Resin system selection: Choosing the right resin family (epoxy, BMI, phenolic, thermoplastic, etc.) for temperature, chemical, and processing demands ensures durability and consistency.

The Role of Prototyping

Prototyping validates assumptions and refines designs before production. In composites, it’s an essential step that reduces risk and builds confidence.

GP&C’s Edge

At GP&C, precision engineering defines everything we do. We don’t just select materials—we optimize fiber architecture, resin systems, tooling, and processes for the environments our parts will face. Prototyping is built into our approach, ensuring performance scales with production.

Why It Matters

In composites, there’s no margin for error. Precision engineering ensures parts perform not just in theory, but in practice—exactly as intended, every time. At GP&C, that’s what we mean by precision in every fiber.