Why Frac Plugs Are So Important

In hydraulic fracturing, frac plugs may be small, but they are absolutely critical to success. These temporary barriers isolate sections of a wellbore, allowing operators to control pressure and direct energy stage by stage. By enabling multistage fracturing, frac plugs ensure that each section of the formation is stimulated in sequence, maximizing hydrocarbon recovery.

Each plug sets the stage for the next, ensuring the frac unfolds exactly as designed. If a plug fails to hold, seal, or release properly, it’s more than an inconvenience—it can jeopardize the entire operation. Failures lead to lost time, costly interventions, and in some cases, compromised safety.

As unconventional wells reach greater depths, higher pressures, and hotter environments, frac plugs must withstand extreme conditions. They are expected to tolerate:

– High differential pressures to maintain isolation.

– Elevated temperatures that can degrade materials.

– Corrosive fluids and proppants that can weaken structural integrity.

– Predictable removal or dissolution after stimulation to allow production flowback.

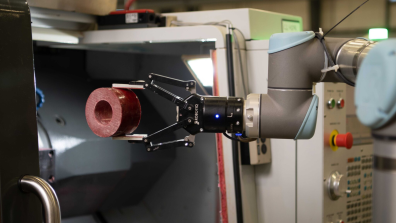

Modern frac plug design often uses advanced composite materials to balance strength, modulus, and controlled degradation. This allows plugs to perform reliably during stimulation and then be easily drilled out or dissolved when no longer needed.

At GP&C, we engineer composites that rise to these challenges. By precisely tailoring material properties, we deliver frac plugs that perform with consistency in the harshest conditions. Reliable plugs keep wells producing—and keep the entire frac process on track.