How Fiber Selection Impacts Performance

When it comes to composite design, fiber selection is everything. The type of fiber used in a material system determines how it will behave under stress, how it will endure over time, and ultimately whether it will succeed in demanding applications.

Strength, Stiffness, and Beyond

Different fibers bring different performance profiles:

- Carbon fibers deliver the highest stiffness-to-weight and strength-to-weight ratios, making them essential for aerospace and defense applications where every ounce counts.

- Glass fibers are cost-effective and provide excellent toughness, though with lower stiffness. They are widely used in oilfield, marine, and automotive applications.

- Aramid fibers (like Kevlar®) excel in toughness and impact resistance, often selected where durability and energy absorption are critical.

Each option comes with trade-offs, and knowing how to balance them is at the heart of engineering composites.

Performance Under Pressure

It’s not just about peak strength. Fibers influence how a component will perform under temperature extremes, cyclical loads, creep stresses, and corrosive environments.

- Carbon fibers resist fatigue and creep exceptionally well, extending service life under repeated loading.

- Glass fibers perform reliably in static and moderate environments but can degrade faster under fatigue or stress corrosion.

- Aramid fibers absorb energy but require protective coatings to withstand UV exposure, moisture, or heat.

That’s why a downhole oilfield plug demands a very different fiber system than an aerospace panel—and why sporting goods require yet another balance of properties.

The Expanding Fiber Toolbox

In addition to carbon, glass, and aramid, emerging fibers are expanding design options:

- Basalt fibers: Offer higher chemical resistance than glass and are more affordable than carbon.

- Natural fibers (flax, hemp, jute): Sustainable alternatives being tested in automotive and consumer goods.

These alternatives provide new ways to optimize for cost, sustainability, and performance.

The Precision of Selection

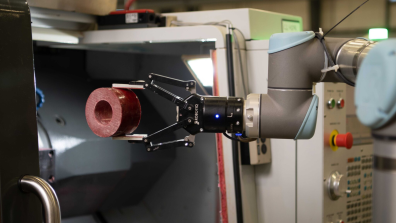

At GP&C, fiber selection isn’t a one-size-fits-all decision—it’s a tailored process. We weigh the requirements of each application—strength, stiffness, fatigue resistance, cost, environmental durability, and manufacturability—to deliver the right balance. It’s this precision that ensures our composites perform in the field, not just in the lab.

Why It Matters

The wrong fiber choice can mean premature failure, added cost, or even safety risks. The right choice unlocks performance, reliability, and efficiency.

For industries that cannot afford compromises, understanding how fiber selection impacts performance isn’t just good engineering—it’s mission critical.

At GP&C, we bring Precision in Every Fiber to life by matching the right fiber system to every application.