In extreme environments, fiber strength alone won’t guarantee performance. The resin system—responsible for binding fibers, transferring loads, and protecting against heat and chemicals—often determines whether a composite part succeeds or fails. As industries like oil & gas and aerospace push deeper into high-temperature applications, the demand for next-generation resins is reshaping the field.

Why High-Temp Resins Matter

At elevated temperatures, conventional epoxies can lose stiffness, creep under load, or degrade chemically. High-temp resins expand the operating envelope, enabling composites to perform reliably at 300°F, 400°F, or beyond. This is especially critical in downhole drilling, where heat, pressure, and corrosive fluids converge, and in aerospace, where thermal cycling is a constant challenge.

Emerging Chemistries

Several resin systems are gaining traction as industries look for higher temperature resistance without sacrificing processability:

- Bismaleimides (BMI): Known for toughness and stability up to ~500°F, BMIs are increasingly used in aerospace components.

- Polyimides: Offering extreme heat resistance (up to ~700°F), these resins are ideal for space and jet engine applications, though processing complexity remains a barrier.

- Phenolics: Valued for inherent flame resistance, they are evolving with improved formulations that boost strength and durability.

- High-Performance Epoxies: New chemistries are pushing epoxy limits with enhanced glass transition temperatures, making them viable for harsher environments than before.

- Thermoplastics (PEEK, PEKK): While not new, they are advancing with better processing methods, offering re-moldability alongside thermal stability.

- Benzoxazines: Newer chemistry with higher Tg than standard epoxies, excellent flame/smoke/toxicity (FST) properties, and lower shrinkage. Gaining aerospace traction as an epoxy alternative.

- Cyanate Esters: Excellent thermal stability (up to ~500°F), low moisture absorption, and low outgassing. Widely used in space and satellite applications where dimensional stability is critical.

What’s Coming Next

The next frontier in high-temp resin chemistry is balancing performance with manufacturability. Emerging solutions are focused on:

- Faster curing cycles without sacrificing stability.

- Enhanced chemical resistance for aggressive service environments.

- Hybrid systems that combine thermal stability with damage tolerance.

- Resin Transfer Molding (RTM)-friendly high-Tg systems with lower viscosity for automated infusion and scalable production.

- Next-gen chemistries designed to withstand supercritical CO₂, acids, and high-pressure brines—critical in downhole oil & gas and geothermal applications.

- Digital modeling and advanced testing methods are also accelerating adoption, allowing engineers to simulate resin behavior under extreme conditions before a single prototype is built.

GP&C’s Take

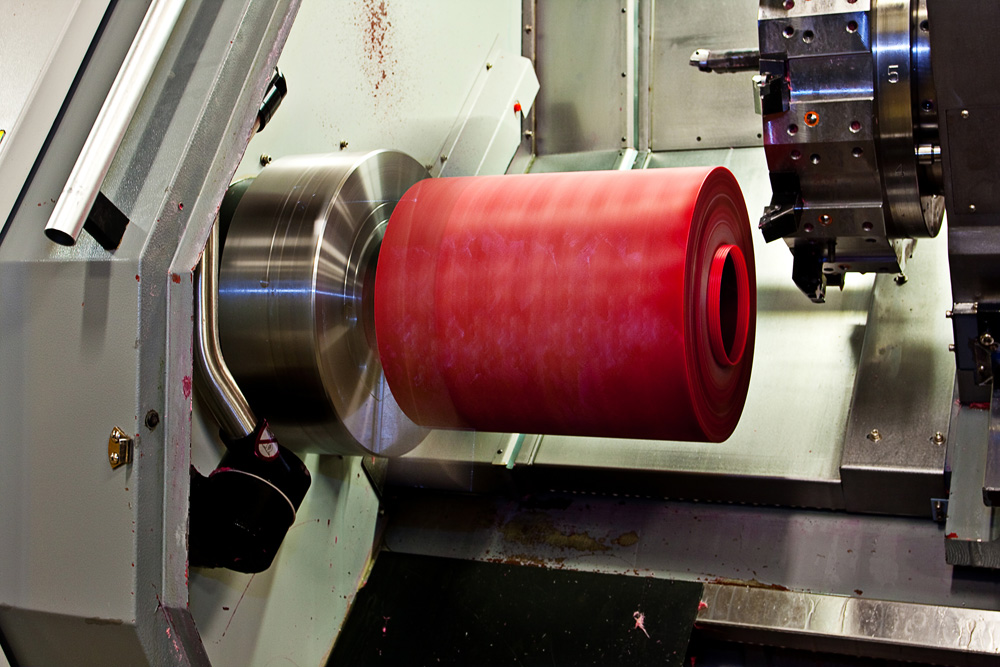

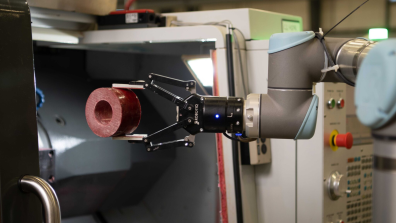

At GP&C, we view resin selection as a cornerstone of composite performance. Our engineers work at the intersection of fiber, resin, and process, tailoring systems that withstand the toughest demands. Whether it’s a frac plug that holds at 400°F or an aerospace panel that endures thermal cycling, we engineer with tomorrow’s chemistries in mind.

High-temp resins aren’t just materials—they’re enablers of performance. And staying ahead of what’s new and what’s next is how we deliver precision in every fiber.