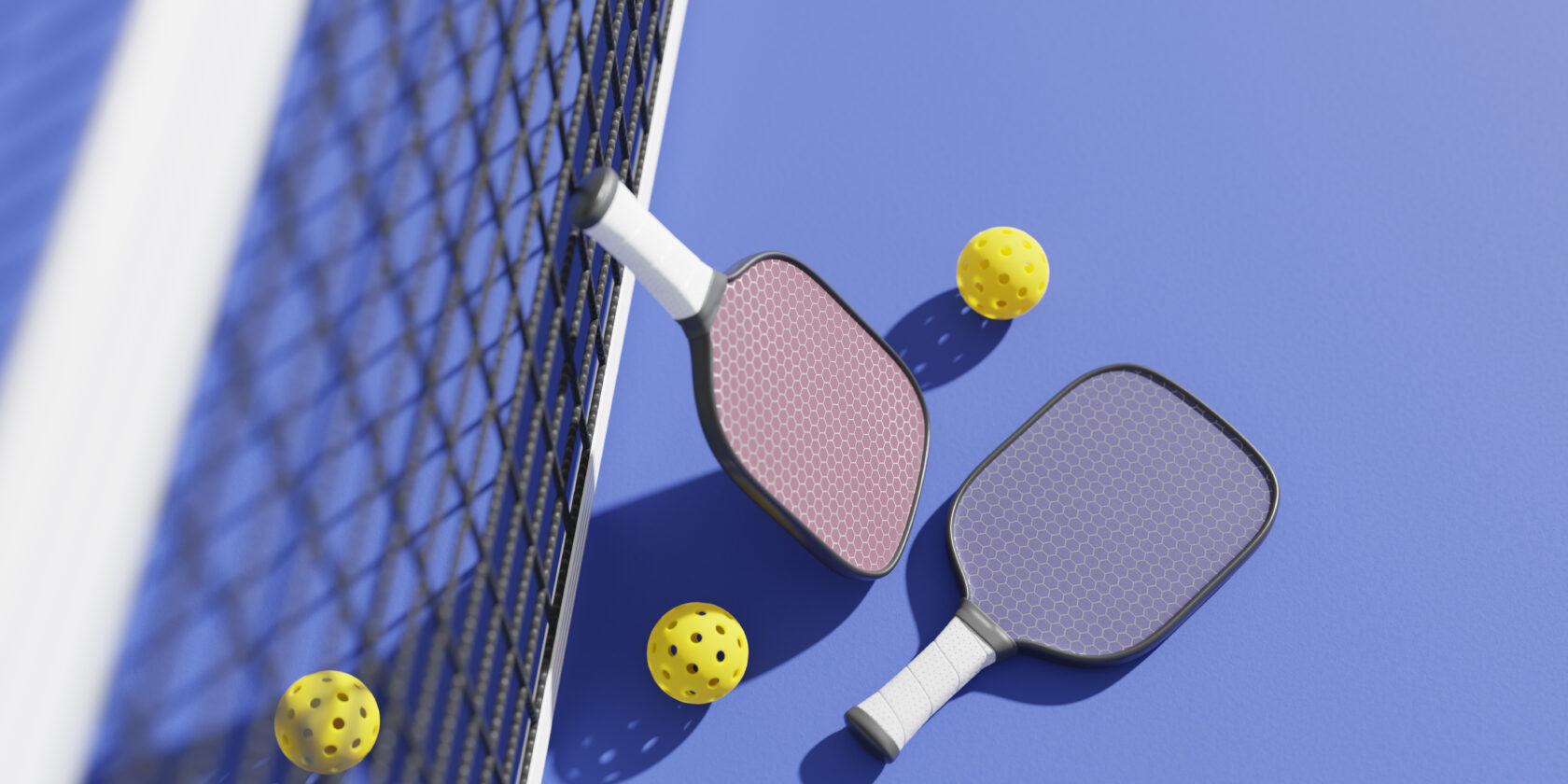

From the Field: How Composites Are Shaking Up the Pickleball Industry

Pickleball is booming—and so is innovation around the paddle. What was once a simple wood design has evolved into high-performance gear, thanks to advanced composite materials.

Why Composites?

Composite paddles combine strength, light weight, and stiffness, giving players more power without sacrificing control. Carbon fiber faces create a crisp, responsive strike. Fiberglass layers add flexibility and spin. Hybrid layups allow brands to fine-tune the balance for every style of play.

Recent advances include thermoformed paddles with unibody construction for greater durability, honeycomb polymer cores reinforced with carbon or aramid fibers for vibration damping, and textured composite surfaces designed to maximize spin while staying within USAPA regulations.

Performance Meets Playability

The right fiber system doesn’t just make paddles lighter—it makes them smarter. Players experience:

– Faster reaction time with reduced weight.

– More consistent shots from optimized stiffness.

– Durability that withstands thousands of high-impact hits.

– Reduced vibration and improved comfort, protecting players from fatigue and repetitive strain injuries.

It’s the same material science trusted in aerospace, defense, and oil & gas—now applied courtside to enhance both performance and player safety.

Market Impact

Composites aren’t just changing how paddles perform—they’re changing the business of pickleball. Premium composite paddles command higher price points, drive brand differentiation, and fuel a fast-growing accessories market. As pickleball expands globally, composites will remain central to how manufacturers innovate for competitive and recreational players alike.

GP&C’s Take

At GP&C, we know composites are more than materials—they’re performance enablers. By balancing tensile strength, modulus, impact resistance, and process precision, we engineer solutions that can transform entire industries. From the oilfield to aerospace—and now to the pickleball court—GP&C delivers precision in every fiber.