From the Field: Downhole Tools Surviving High-Temp Frac Conditions

In high-temperature frac environments, heat, pressure, and aggressive fluids combine to push materials past their limits. Bottom-hole circulating temperatures often exceed 300–400 °F (150–205 °C), while pressures reach 10–15 ksi. Under these conditions, conventional metals and polymers can soften, creep, crack, or chemically degrade—risking seal failure, stuck tools, and costly downtime.

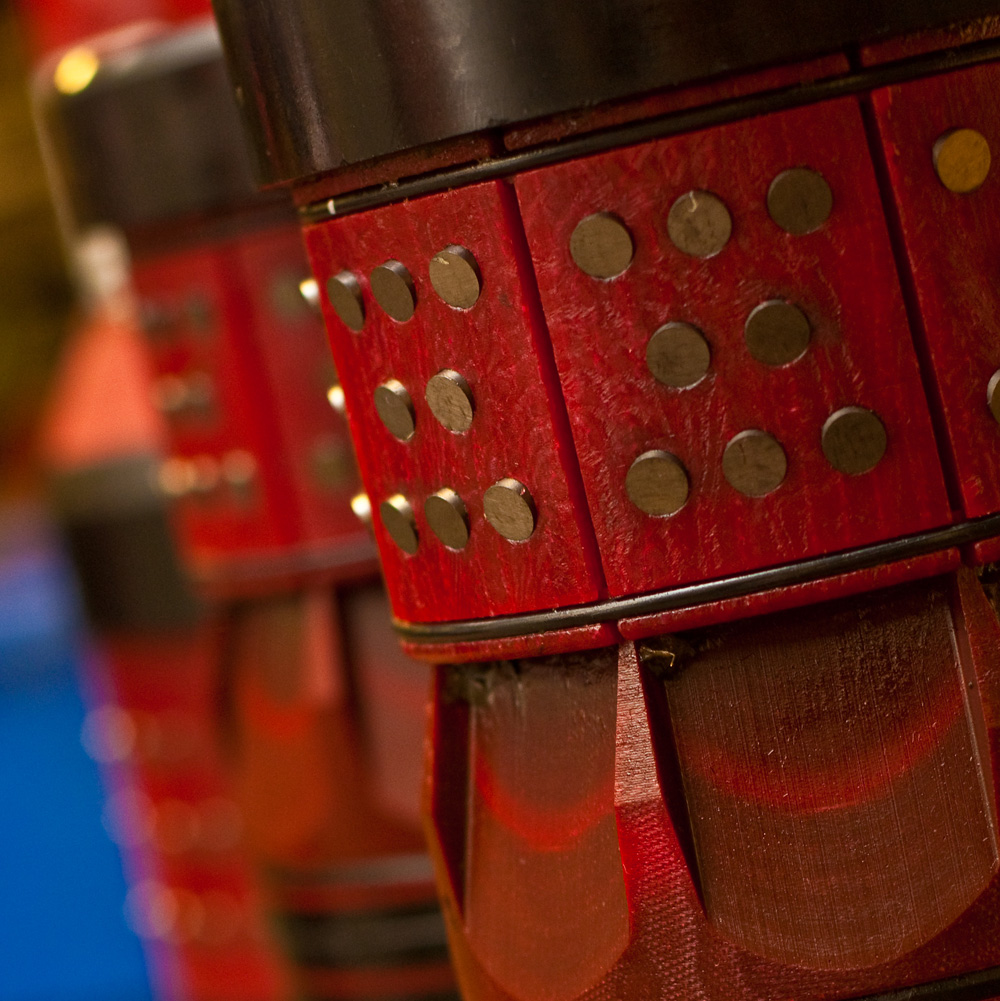

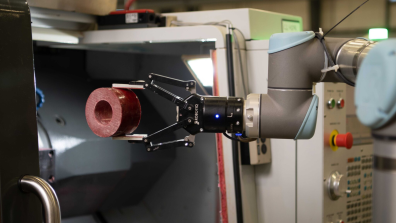

This is where engineered composites excel. The right pairing of fiber architecture, high-Tg resin, and precision design delivers plugs, packers, bridge plugs, seats, and other components that retain strength, resist chemical attack, and hold tolerances through repeated thermal cycles.

At GP&C, we balance tensile strength, modulus, and thermal stability to create predictable, repeatable performance across the frac cycle. The result: fewer failures, faster runs, and lower total cost in the toughest wells.

That’s precision in every fiber.