From Concept to Composite: The Journey of New Product Development

Bringing a new composite product to market isn’t just about materials—it’s about process. At GP&C, our New Product Development (NPD) program is designed to take ideas from concept to production with speed, precision, and confidence.

A Collaborative Start

Every successful project begins with alignment. Early collaboration helps define the essentials:

- Design requirements that guide engineering choices.

- Tooling needs tailored to the complexity of the part.

- Testing requirements that ensure compliance and reliability.

- Timelines for each stage of development.

- Commercialization plans to bridge prototype and production.

In addition, collaboration includes early material selection criteria—identifying the right fiber type, resin system, and matrix compatibility based on environmental resistance and performance. Our engineers leverage CAD/FEA models and digital twin simulations to validate concepts before tooling, reducing risk and accelerating time to prototype.

These conversations set the stage for an efficient, transparent development process that keeps all stakeholders on the same page.

Speed Meets Structure

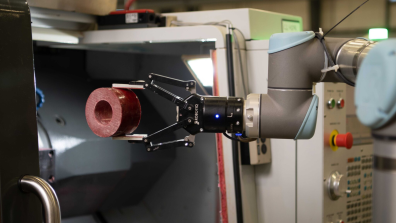

Our goal is to deliver your composite manufacturing project in three weeks or less, depending on complexity. That speed is supported by a dedicated NPD manufacturing cell, where prototypes and first articles are built with the same care as full-scale production.

A detailed Microsoft Project plan is created for each program, outlining tasks, timelines, and responsibilities. This roadmap ensures nothing is left to chance and that every milestone is clearly visible. During this stage, we also integrate Design for Manufacturability (DFM) and Design for Assembly (DFA) considerations to ensure tooling and processes align with part geometry, resin flow, and fiber architecture.

Quality at Every Step

Precision doesn’t stop at prototypes. A tailored quality plan and ITPs (Inspection Test Plans) are integrated into the process from the start, ensuring that every deliverable meets the required standards before moving forward.

Testing and quality requirements are in compliance to ASTM, ISO, or API standards depending on industry. By the time a product transitions to production, both performance and quality are proven.

From Prototype to Production

The NPD team doesn’t just hand off once a prototype is complete—they manage the transition into commercialization and production. That means scaling efficiently, maintaining quality, and ensuring the final product performs exactly as designed in the field.

This includes full support for customer and regulatory qualification requirements. Material and fiber choices are validated through rigorous testing, and complete data packages provide traceability. We also apply lean manufacturing practices and statistical process control to ensure consistency at scale.

Why It Matters

In industries where reliability is mission critical, there’s no room for trial and error. GP&C’s NPD process provides a clear path from concept to composite, minimizing risk while accelerating time to market. By combining collaboration, speed, and precision, we help customers move from idea to impact—without compromise.

At GP&C, new product development isn’t just about making parts. It’s about building trust, delivering performance, and proving precision in every fiber.