Fiber Orientation: The Hidden Driver of Composite Performance

When it comes to composite materials, most people think first about the fibers themselves—carbon, glass, or aramid. But just as important as the type of fiber is how those fibers are oriented within a part. Fiber orientation is the hidden driver that dictates whether a composite structure is strong, flexible, durable, or prone to failure.

Why Orientation Matters

Composites derive their strength from fibers carrying loads. Align those fibers along the direction of stress, and the part will be exceptionally strong. Misalign them, and the same material may weaken dramatically. A panel with fibers oriented at 0° can excel in tensile strength, while the same panel with fibers at 90° may be vulnerable under load. Intermediate angles such as ±30° or ±60° are often used to fine-tune torsional or hoop performance, especially in aerospace and pressure vessel applications.

The secret lies in tailoring orientation to match real-world performance demands and the specific load cases a part will experience.

Design Flexibility Through Layup

Unlike metals, which are isotropic and perform the same in every direction, composites are anisotropic—their properties change with fiber alignment. Engineers can take advantage of this by using multi-directional layups. For example:

– 0° fibers maximize strength along the length of a component.

– ±45° fibers improve shear and torsional performance.

– 90° fibers add stability across the width.

– Quasi-isotropic layups (0°/±45°/90°) approximate isotropic behavior, distributing loads evenly and improving multi-axial performance.

By stacking layers in different orientations, designers create a part that balances stiffness, strength, and durability for its intended environment.

Real-World Impacts

The effects of fiber orientation show up across industries:

- Aerospace: Wings, fuselage panels, and pressure vessels rely on carefully designed orientations to carry aerodynamic loads, pressurization forces, and torsional stresses.

- Oil & Gas: Downhole tools must withstand combined stresses from pressure, torque, and temperature—demanding optimized layups that maintain integrity under thermal and chemical exposure.

- Sporting Goods: In pickleball paddles, tennis racquets, and bicycles, orientation determines whether a product feels rigid and powerful or flexible and forgiving.

In each case, orientation decisions can make the difference between high performance and early failure.

Failure Modes and Manufacturing Considerations

Misaligned or poorly controlled fiber orientations can lead to premature failure modes such as:

– Delamination from uneven stress transfer.

– Matrix cracking when transverse stresses exceed resin capacity.

– Fiber microbuckling under compressive loads.

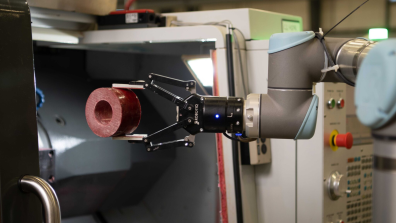

Manufacturing processes also play a role. Hand layup, filament winding, pultrusion, and resin transfer molding each influence fiber angles differently. Even small shifts during layup or curing can alter performance. Automated Fiber Placement (AFP) and tape laying help maintain precise orientation control, improving consistency at scale.

Environmental Effects

Fiber orientation not only affects structural strength but also how composites respond to real-world conditions. Orientation influences thermal cycling tolerance, fatigue resistance, and moisture ingress—all critical considerations in oil & gas, aerospace, and other demanding environments.

GP&C’s Approach

At GP&C, we treat fiber orientation as a core element of design—not an afterthought. Our engineers use advanced modeling, automated technologies, and real-world testing to determine the optimal layup for every application. We balance performance requirements with manufacturing efficiency to ensure that orientation choices deliver both reliability and scalability.

This precision allows us to deliver composites that are stronger where they need to be, flexible where they should be, and durable no matter the conditions.

Why It Matters

Fiber orientation may be invisible to the end user, but it’s one of the most powerful levers in composite engineering. By controlling it, we unlock performance that metals can’t achieve and ensure that every part is built for its mission.