Engineer’s Edge: Why Thickness Uniformity Is Harder Than It Sounds

Getting a composite part to the right thickness sounds simple—but it’s not. Heat flow, resin distribution, fiber orientation, and tooling all interact in ways that make uniformity a constant challenge.

Even small variations can create resin-rich pockets, thin spots, or internal stresses that affect performance. That’s why precision process control is just as important as material selection.

At GP&C, we tackle this with carefully designed tooling, controlled resin flow, and tightly monitored cure cycles. Our engineers model how materials behave in the mold, then validate with testing to ensure every part meets exact tolerances. It’s this balance of design and discipline that keeps thickness uniform—and in composites, consistency is performance.

Additional Considerations:

- Thermal Gradients & Cure Dynamics – Uneven heating during cure can cause localized resin flow or differential shrinkage, especially in thick laminates or parts with variable cross-sections where the center may lag behind the surface in reaching full cure.

- Complex Geometries – Corners, tapers, and varying ply drop-offs often introduce non-uniform resin migration and compaction pressure, making thickness control especially challenging compared to flat panels.

- Fiber Volume Fraction (FVF) – Small changes in FVF have an outsized impact on thickness and performance. Achieving target FVF requires careful control of consolidation pressure, resin viscosity, and venting.

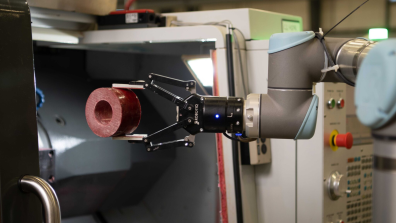

- Process-Specific Challenges – Autoclave & Vacuum Bagging: Bag wrinkles, bridging, or inadequate bleeder/breather setup can create localized thickness variations. Resin Transfer Molding (RTM): Flow front race-tracking or uneven permeability can produce resin-rich or resin-starved regions. Filament Winding

- Tape Placement – Tension inconsistencies and gaps between tows cause thickness variability.

- Inspection & Quality Control – Non-destructive testing (ultrasonic C-scan, laser profilometry) is often used to detect thickness variation before a part goes into service. Real-time monitoring (e.g., dielectric sensors) is becoming more common for in-situ cure control.

- Industry Implications – Aerospace and energy sectors often require ±0.005–0.010 in. tolerance on thickness across large parts. Even minor non-uniformities can lead to part rejection, rework, or reduced service life.