Engineer’s Edge: The Difference Between Tensile Strength and Modulus

When engineers talk about material performance, two terms often come up: tensile strength and modulus of elasticity. While they’re related, they measure very different things.

- Tensile Strength: The maximum stress a material can withstand before breaking. It is usually expressed in megapascals (MPa) or pounds per square inch (psi).

- Modulus of Elasticity (Stiffness): A measure of how much a material resists deformation under stress. In this context, modulus usually refers to Young’s modulus, which is expressed in gigapascals (GPa).

Why does this matter? In applications like aerospace components or downhole tools, a material might be strong but too flexible—or rigid but too brittle. Understanding both properties is critical for designing parts that don’t just survive stress, but perform reliably under real-world conditions.

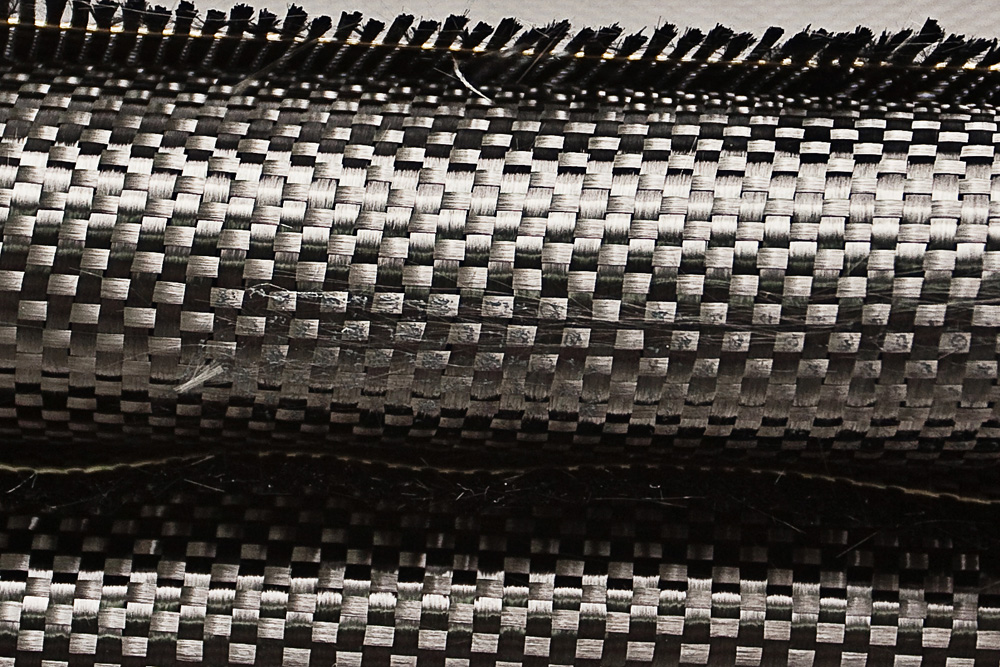

For example, carbon fiber has both high tensile strength and high stiffness, making it ideal for structural aerospace parts. By contrast, aluminum is relatively stiff but not as strong by weight, while certain polymers can be strong but too flexible for structural use.

In composites, engineers can fine-tune these properties by selecting fiber types, adjusting fiber orientation, and choosing resin systems. This allows us to create engineered solutions that balance tensile strength and stiffness for the unique demands of each project.

At GP&C, we engineer composites that achieve the right balance of strength and stiffness for mission-critical environments.

Have questions about your project? Click here to contact us today.