Are Thermoplastic Composites the Future of Aerospace Components?

Aerospace engineering has always been about reaching further — lighter aircraft, stronger structures, and more efficient performance. For decades, thermoset composites have been the material of choice, trusted for their proven strength and reliability. But a new class of materials is quickly changing the conversation: thermoplastic composites. With unique advantages in production, sustainability, and performance, they are emerging as a key force in shaping the next generation of aerospace components.

What Makes Thermoplastic Composites Different

At their core, thermoplastic composites combine high-performance polymers (such as PEEK or PEKK) with reinforcing fibers (carbon fiber, glass, or aramid). Unlike thermosets, thermoplastic resins don’t permanently cure — they can be reheated, reshaped, and even recycled. That fundamental difference opens new possibilities for engineers and manufacturers:

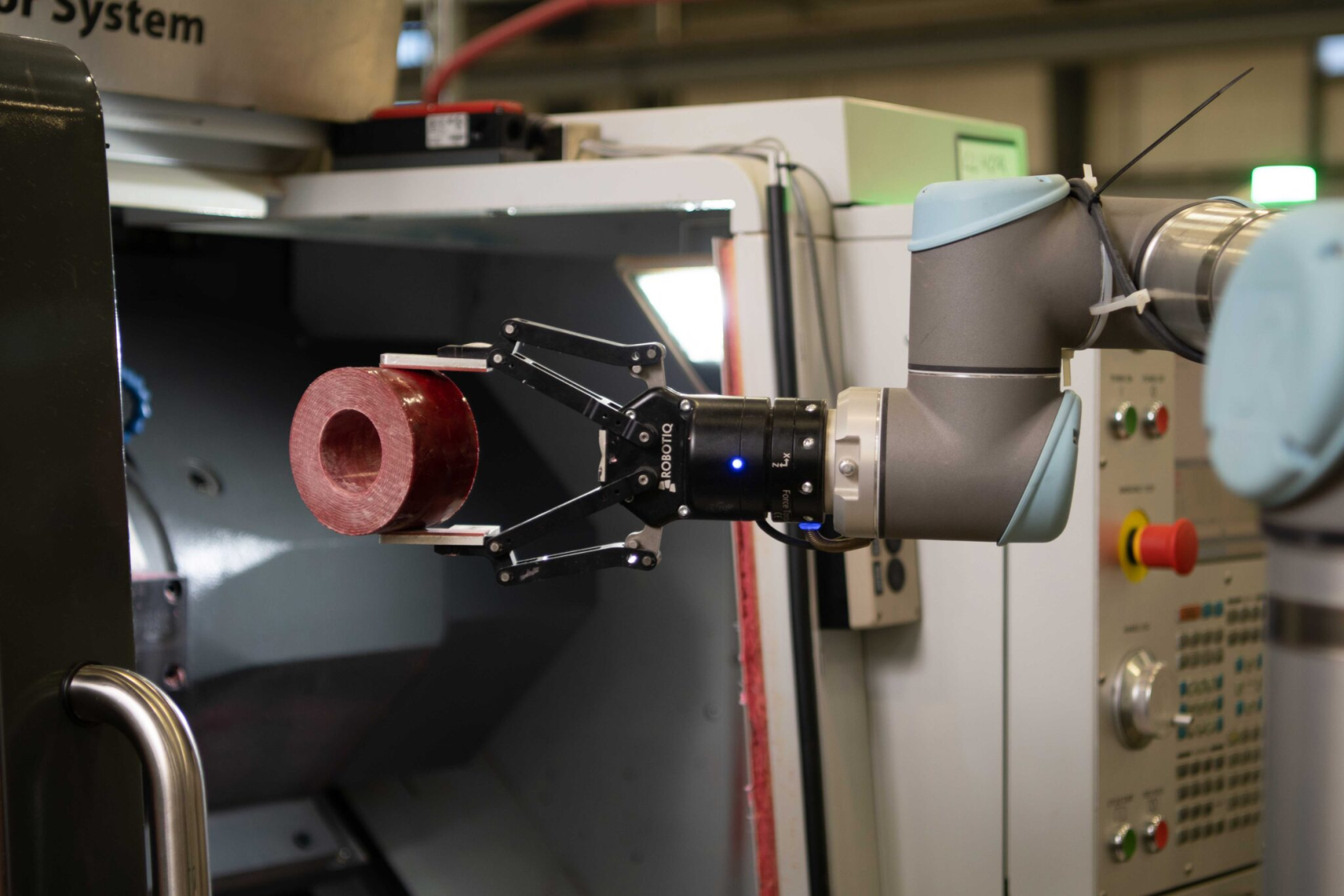

- Faster production cycles – no long cure times, enabling shorter lead times and compatibility with automated processes like automated fiber placement and press forming.

- Recyclability – scrap material can be reused, aligning with aerospace sustainability and net-zero goals.

- Toughness and impact resistance – strong durability under stress, reducing maintenance and extending service life.

- Weldability – parts can be fused without rivets or fasteners, reducing both weight and assembly complexity.

Meeting Aerospace Standards

Aerospace isn’t forgiving — every component must withstand extreme forces, heat, and stress while keeping weight to a minimum. Thermoplastic composites are rising to that challenge. Reinforced with carbon fibers, they demonstrate:

- Strength-to-weight ratios comparable to or better than thermosets.

- Thermal performance sufficient for many high-demand applications.

- Design flexibility that allows for more efficient, integrated structures.

Today, we already see thermoplastic composites in seat structures, brackets, clips, fuselage panels, and secondary structural parts. With continued advances, primary load-bearing roles are on the horizon. Airbus and Boeing have both introduced thermoplastics into next-generation programs, underscoring their growing acceptance in the supply chain.

Challenges and Considerations

Despite the benefits, adoption of thermoplastic composites is not without hurdles. High-temperature resistance remains a limitation for some extreme-heat environments, such as engine components. Upfront costs for automated processing equipment are significant, even though they reduce long-term production costs. Most importantly, aerospace certification is a rigorous, time-intensive process — qualifying new materials and processes can slow deployment across platforms. Still, the trend is clear: thermoplastics are expanding their footprint as suppliers and OEMs seek faster, leaner, and more sustainable solutions.

Looking Ahead

The future of aerospace materials won’t be defined by choosing thermosets or thermoplastics, but by using both where they make the most sense. Thermosets will continue to dominate certain high-performance, high-temperature applications, while thermoplastic composites expand their role in areas where speed, sustainability, and impact resistance are priorities. For engineers, this means more tools in the toolbox — and more opportunities to innovate.

From Insight to Implementation

At General Plastics & Composites, precision isn’t just a value — it’s a standard we prove every day. As an AS9100D-certified manufacturer, we meet the rigorous quality requirements aerospace demands, ensuring every component we deliver is reliable, traceable, and ready for flight.

Our expertise spans both thermoset and thermoplastic composites, giving engineers the flexibility to explore new materials without compromising performance or compliance. Whether it’s scaling production, tailoring a solution, or advancing next-generation aerospace components, our team is built to help programs move from possibility to production.